automatic capsule filling machine working principle

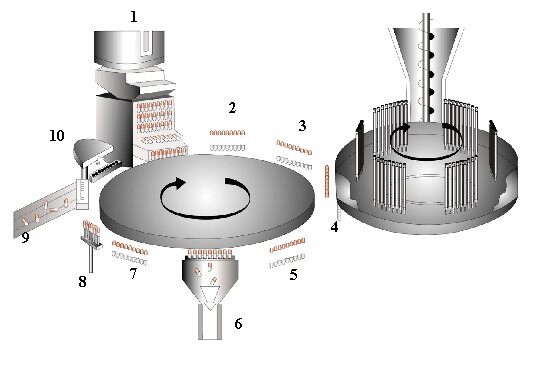

The powders are transferred from one tamping punch to next to achieve a smooth finish. After starting up the machine the empty capsules in hopper will be fed into the slot of magazine vertically.

I will discuss all the three working principles of automatic encapsulation machine here.

. If you run a large scale production firm then using automated capsule filler is a must. Beneficial performance for users. Lets see how these machines work.

The liquid filling machine works when the pressure is high. Send an inquiry for any of your capsule filling machines. Capsule filling machines should all have the following operating principles in common.

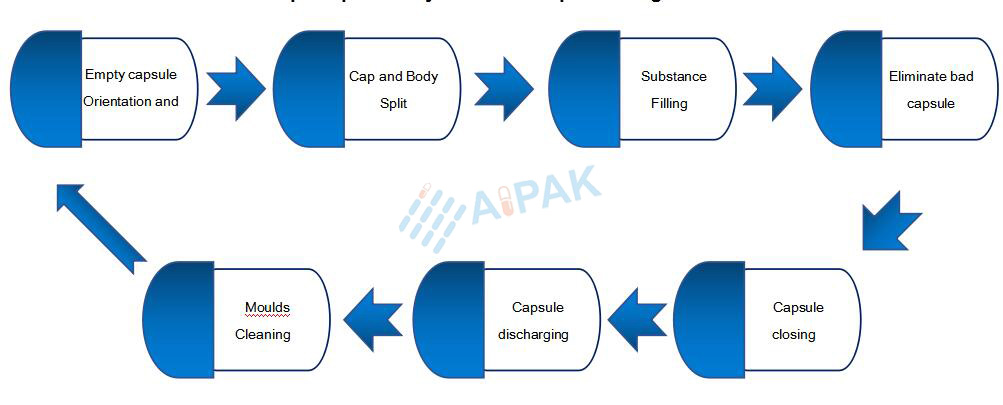

The working principle of dosator capsule filling machine is simple and can easily be adapted to. Locking of the. Separation of capsule caps from bodies.

The principles of the machines are as follows. These machines boost production and improve the efficiency of the production process. The machine can alarm and stop running automatically.

It shows how many capsules the machine can fill per time and affect the maximum filling speed. This can be classified as liquid pressure filling which means the liquid flows into the bottle based on its own weight when the amount of pressure of the liquid reservoir is equal to the. Different filling weights may be flexible without altering components.

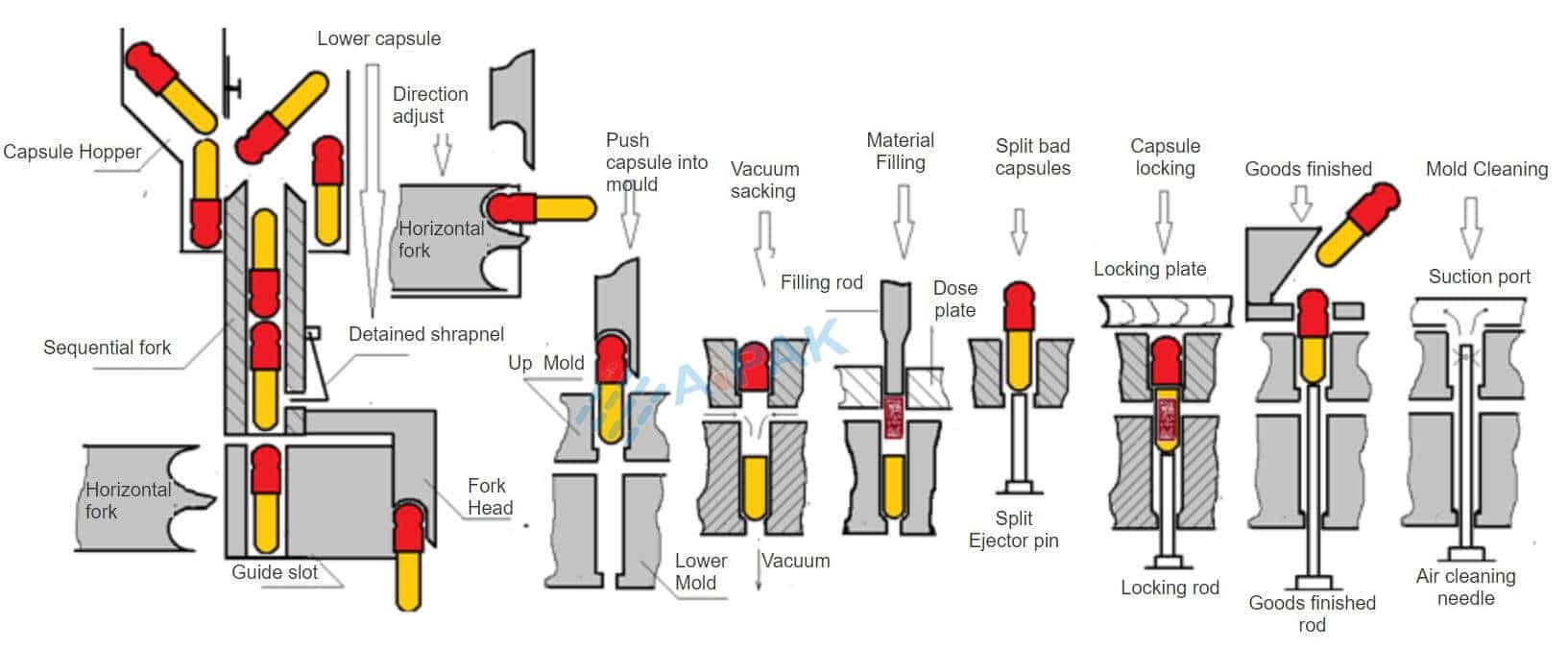

Automatic Capsule Filling Machine. With each stroke of machine the fingers of magazine will release one row of capsules into rectifier raceway. Put the lower mold to the turntable and add the powder to the hopper.

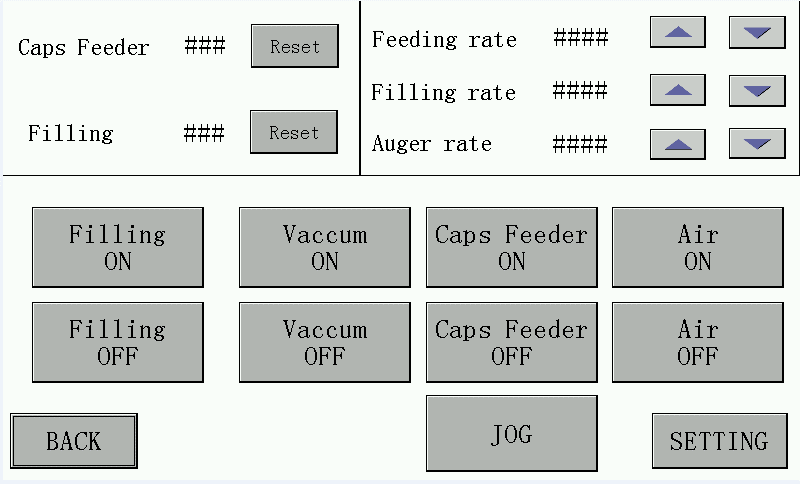

Cover the filled lower mold with the upper mold and move them to the locking. Take our NJP series automatic capsule filling machine as an example. Start the capsule filling machine.

Liquid Filling Machine Its Principles. Output up to 12000 pcshr. These capsules fillers are divided into 2 categories depending upon their uses ie personal capsule filling machine professional capsule filling machine.

Most automatic capsule filling machines can fill capsule of different sizes by changing mold. Compressed Powder slug is inserted into the capsule. Dosing of fill materialformulation filling the bodies.

Pharmaceutical processing is a series of steps and capsule filling is an important part of the process. Over 5000 happy customers. Working Principle of Automatic Capsule Filler Machine.

In typical applications the capsule filling machine manufacturer may modify the machine to suit a wide range of applications. After that the material is filled in the capsules with the help of powdergranule filler present in the capsule filler machine then the caps and body are rearranged in the machine itself. It can be done by a number of different methods.

SaintyCos top selling products include. Working principle of automatic capsule filling machine. Capsules are fed into the segments and separated by negative suction.

Automatic Capsule Filling Machine is acceptable for capsules from sizes 00 to 4 and may be fed with various kinds of powder granules legumes. Automatic Capsule Filling Machine Working Principle. 586 Now the capsules flow can be started.

In stock ready to ship. Rectification orientation of the bad gelatin capsules. Personal capsule filling machines is for small scale production and utilization.

Working Principles of Various Filling Machines. Press the filling button ON to fill the capsule. New closed structure in line with GMP requirements.

The capsule filling machine work on certain principles. Closing of the body and cap. Browse through 75 Used New Filler Powder Capsule Machines.

587 The capsule starts moving forward in the sorting plate. The capsule filling machine is an automatic capsule filling machine by which the separation filling and sealing of capsules can be carried out automatically. Automatic capsule filling machine is a very important machine in pharmacy industry.

An automated filling machine will take care of the entire filling process itself. This machine is a device for filling powder granules or small pieces into hollow capsules. SaintyCo manufactures all types of capsule filling machines including tamping pin capsule filling machine automatic capsule filling machine semi-automatic capsule filler and more.

In this station the upper and lower parts of the capsule body are separated by vacuum suction. The machine can greatly improve production efficiency and reduce labor costs. Capsules must be properly processed and filled with capsule filler prior to shipment.

Capsule filler is a type of machine used to fill empty capsules with pharmaceutical ingredients. Stable operation safe and reliable. 1 Empty capsules are discharged from the capsule hopper and pushed into position 1 sequencing station orderly by the push rod through the capsule tank.

NJP-2500C Full Automatic Capsule Filler Machine is an intermittent motion and hole plate type filling full automatic capsule filler equipment. This can be done manually or with the help of an automatic capsule filling machine. The product adopts plug filling intermittent.

With the function of auto detection when insufficient powderinsufficient capsules optional function and. Filling structure is handled by modularity as well as precious design reliability and low wear and tear. The capsule cap is on the upper module and.

51 The Working Principle of Softgel Encapsulation Machines. Our capsule filling machine can manufacture capsule size vary from size 00 0-4. The body of the capsule is transferred to the filling station where the active ingredients are filled in the capsule.

Httpswwwcapsulemachinesin demostrating Capsule Filling Machine Working Principal which shows Functional Principle of Capsule Filling Process. Operating principles of a capsule filling machine. It adopt optimization design for meeting the characteristics of Chinese medicine and the requirement of GMP it has the characteristics of compact mechanism small volume lower noise precision filling.

When the fork is sent down six capsules are delivered at a. Request A Quick Quote. As you can see the working principle of dosator type capsule filling machine is quite simple and straightforward thou it may seem complicated after assembling the machine.

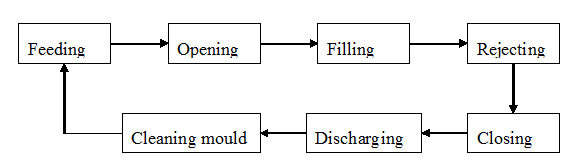

Rejoining of caps and bodies. If the movement is slow and the capsules start clogging then increase the vibration slowly by turning the regulator knob clockwise. You can also look for the automatic capsule filling machine through the web.

The powder here is compacted with the help of a tamping punch. Continue reading Capsule Filling. Batch sizes can range from a few hundred to tens of thousands of dosage units.

Automatic Capsule Filling Machine may also be used to meet herbal powder health food organic food and complex powder substances. You can also look for the best pill filler through. The main working principle of the automatic capsule filling machine is that when the machine is running the capsules in the capsule hopper will vertically enter the delivery fork one by one.

Working Principle of Capsule Filling Machine. First the capsule caps are divided from their bodies. Reserved for Pellet or micro tablet filling Optional Ejection of faulty or defective capsules.

The complete functioning of an automated capsule filling machine is detailed below. Ad Wide range of capabilities from sterile injectables to solid dosage form products. Fully automatic capsule filling machine semi-automatic capsule filling machine and manual capsule filling machine.

6 holes for 9 holes for 1200C 18 holes for 2000C and 24 holes for 3500C. Ad Rent buy or lease Filling Capsule Equipment Machines. For capsules with good quality the machine can be run fast while the machine shall run relatively slowly if the capsule quality is not good.

Observe the capsule movement in the sorting plate.

Semi Automatic Capsule Filling Machine Manual Working Principle Ipharmachine

Automatic Capsule Filling Machine The Most Ultimate Importing Guide Capsule Filling Machine Your Best Online Resource About Capsule Fillers

Capsule Filling Machine The Blueprint Guide Saintyco

6 Stations You Must Know To Improve The Filling Quality Of Automatic Capsule Filling Machine Aipak

Automatic Capsule Filling Machine Njp Series Working Principle Ipharmachine

Automatic Capsule Filling Machine High Speed Capsule Filler

Automatic Capsule Filling Machine High Speed Capsule Filler

Njp 800 Automatic Pill Hard Capsule Filling Machine Capsule Making Machine China Capsule Filling Machine Manual Capsule Filling Machine Made In China Com

Semi Automatic Capsule Filling Machine Saintytec

Automatic Capsule Filling Machine Working Principle Ipharmachine

Automatic Capsule Filling Machine Working Principle Ipharmachine

Automatic Capsule Filling Machine High Speed Capsule Filler

How Different Types Of Capsule Filling Machine Work

Filling Machines Their Working Principles

Capsule Filling Machine Fully Automatic Capsule Filling Process Working Animation Project Youtube

Automatic Capsule Filler Encapsulation Machine Njp 1200c Ipharmachine

Encapsulators Operating Principles Types And Sequence Of Events